Tough ABS-like SLA Resin is designed to mimic the properties of Acrylonitrile Butadiene Styrene (ABS) plastic, a common thermoplastic polymer used in traditional manufacturing. This resin is tailored for Stereolithography (SLA) 3D printing, offering a balance between strength and flexibility, which is characteristic of ABS plastic.

Material Composition

This resin is a photopolymer that hardens under UV light. It is composed of a blend of monomers, oligomers, and photoinitiators, along with additives that give it ABS-like properties. These additives are designed to enhance the material’s toughness, impact resistance, and temperature resistance.

Uses

- Functional Prototypes: Ideal for creating prototypes that need to withstand mechanical stress.

- Automotive Parts: Suitable for producing durable parts for automotive applications.

- Consumer Goods: Used in household items and consumer electronics that require toughness.

- Engineering Components: Applicable for engineering parts that need a balance of strength and flexibility.

- Snap-fit Assemblies: Perfect for parts that require snapping or interlocking features.

Best Fit Use

Tough ABS-like SLA Resin is best suited for applications where durability, impact resistance, and a degree of flexibility are required, such as in functional prototypes and engineering components.

Example 1

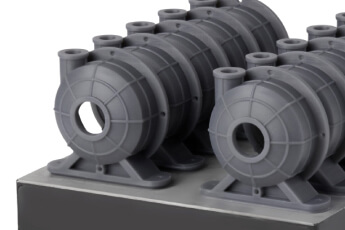

Functional Prototypes: This resin is extensively used in prototyping, especially for parts that need to endure mechanical stresses and strains, such as gears, hinges, and latches.

Example 2

Automotive Parts: In the automotive industry, this resin is used for creating durable components like knobs, handles, and fixtures that require ABS-like properties.

Difference Between Basic and Advanced Forms

The basic form of this resin offers good toughness and impact resistance. Advanced forms may include modifications for higher temperature resistance, increased flexibility, or improved surface finish.

Benefits

- High toughness and impact resistance.

- Good flexibility.

- Suitable for detailed printing.

- Resistant to mechanical stress.

Drawbacks

- More expensive than standard resins.

- Requires post-processing (UV curing).

- Limited shelf life compared to other materials.

Overall Rating for Daily Use

- Hobbyists: 3.5/5 (Great for functional projects but requires careful handling and post-processing).

- Professionals: 4/5 (Highly valuable for industrial applications requiring durability).

Future Developments

Future advancements in Tough ABS-like SLA Resins may focus on enhancing material properties like heat resistance, reducing brittleness, and improving environmental stability. Research may also explore bio-based alternatives to make the resin more sustainable.